My DIY Lathe Steady Rest

by Alan Stratton on Tuesday, August 27th, 2013 | 3 Comments

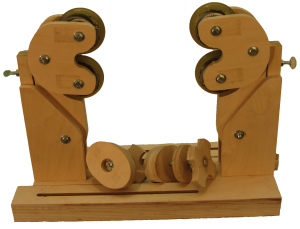

After using my new steady rest turning the travel mug, many viewer requested more information about the steady rest. So here we go.

It’s make from baltic birch plywood with layers glued together as necessary for thickness. The wheels came from a pair of roller blades I purchased at a local thrift store.

It works fine except I’d like to be able to more my tool rest closer when the steady is near the end of the workpiece. I think it can be much closer. But before I modify the base, I’d like your ideas.

I used 1/4 inch hardware. I will be doubling the nuts to prevent them from loosening.

I will appreciate all comments and suggestions for improvements. Thank you in advance.

Hi Alan,

You know, those wheels don’t need to be parallel with the workpiece to stabilise it, so if you could add the ability to rotate the vertical arms and point the wheels at your headstock (along the vertical axis) then that should give you a bit more space for the toolrest. Since the wheels you’ve got have a semicircular profile you should easily be able to turn them in at 45° and still get more than adequate support for your work.

Hadn’t thought of that.

I’ll have to try it.

Thank you,

Alan Stratton

[…] been using my home made steady rest for over a year. During this time, I’ve thought of a couple of […]