In the remote possibility of technical difficulties, this post is also available at YouTube and FaceBook.

Best Right Here!

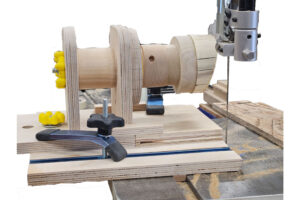

While making last week’s project, it was an appropriate time to upgrade my band saw sled incorporating inspiration from a demonstration at last year’s Rocky Mountain Symposium in Colorado.

In that demonstration, he used a sled that had some features that I thought would be good to incorporate into the sled I have been using and upgrading for several years. One problem – these features depended on a salvaged lathe spindle. The spindle provided a threaded mount and length for stability. My previous sled used a 3D printed knob that held a chuck or threaed faceplate to a 3/4″ plywood.

Then the idea hit. I had also designed and 3D printed a chuck hub that could serve a similar purpose. And, in fact, would be even better and much less expensive.

My new design will cut arc’, sloped cuts, straight cuts, and freehand cuts. For each cut the turning project is mounted to a chuck or threaded faceplate. Then, with the sled, it can be safely cut. This design also enables exact offset cuts by using a spacer inserted behind the plywood base holding the chuck hub. Therefore, all other settings are preserved – no dismantling required for the offset.

Projects that follow John Beaver require offset curve cuts. My Celtic knot vases require offset slant cuts at specific rotations.

Dimensions depend on the bandsaw capacity. I share my dimensions and their rationale in the video. Please adapt to your equipment. Please also share your enhancements.

Chuck hubs and knobs that match popular spindle sizes are available at by Etsy store at

https://www.etsy.com/shop/AsWoodTurnsTools

Universal T-Track hardware, I purchased from HomeDepot.com.

Enjoy.

p.s. If you would like a more in depth demonstration than my weekly videos, please contact me for an IRD (Zoom Demo) on this or other topics.