Woodturning and 3D Printing – Can They Work Together?

This posting is best viewed right here on this page. In case of difficulty, it is also available on YouTube and FaceBook.

Based on questions that came from recent project, this post gives an overview of 3D printing from my perspective as a woodturner.

Even before I purchased a 3D printer, I designed some items that the Maker Space in the local library printed for me.

Since purchasing my printer, I have found many unexpected projects to design and build.

3D printing is considered a rapid prototyping technique. It is not instant but is much faster than milling parts while in the development stage. It does not replace injection molding. However, molds for commercial injection molding range around $100,000 each. That means matching molds for the bushings I used in recent projects could exceed $200,000 each size.

Needless to say, there is a learning curve required. For me, it is worth the effort.

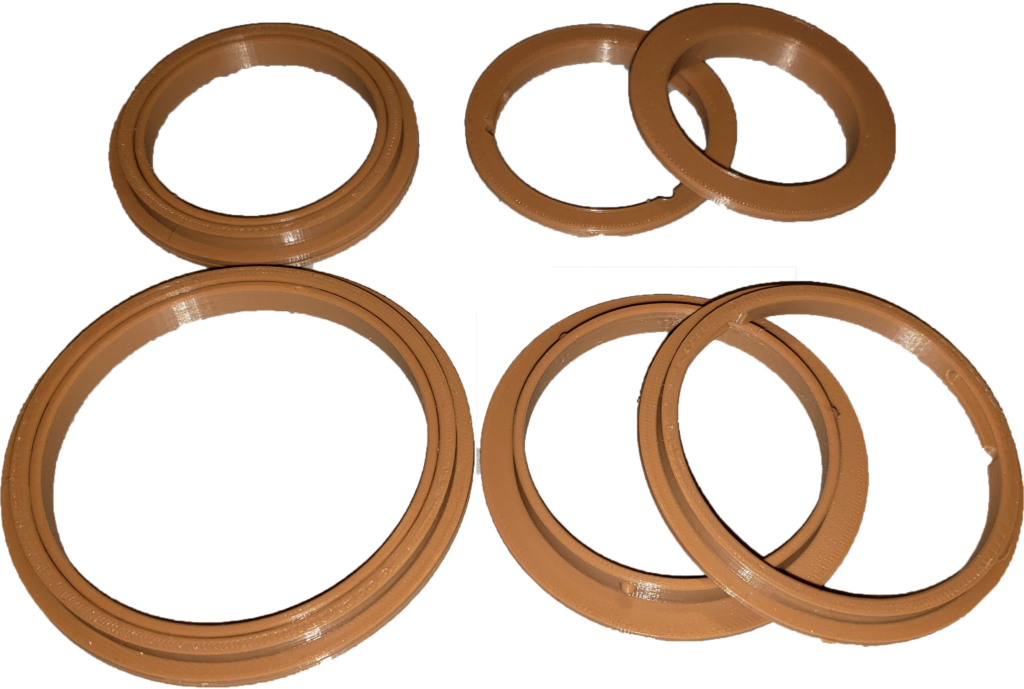

The bayonet bushing are in my Etsy store (link) in 3 colors and sizes from 1″ outer diameter by 1/4″ thru 3″ and then more larger sizes.

Enjoy!

Hi Allen,

Thanks for sending me your information for your Bayonet inserts that I inquired about awhile back in the Acorn Box video you did. I found your current video on your 3D printing endeavors most interesting. 6 months ago I dove into CNC machining to also complement my woodturning, but I find the “learning Curve” most challenging in dealing with all the software issues. Having done the CNC work did make your video more easier to comprehend since the processes are somewhat related. Great Job and will have to try one of your Bayonet mounts…..these look great. Super job on a well done video….very interesting the work your now into.

Yes, the learning curves are significant. No denial there. If you have a hate relationship with computers and coding. probably not the thing.

But, my formal training is accountancy but have used and programmed computers since college. A reasonable foundation to start learning from

Alan

Alan

I enjoy today video on 3D printer and I am new to hobby of turning and can see myself expanding with my growth in turnings and wood working in general being a machinist for 48 years and trying new thing is alway a great thing I found today video great and I will explore further and may consider buying a printer my self like the items you gave shown you u had got your shop i too like to look and find thing to improve and make things easier or better so please keep up the great works of information

Thank you

Donald E Hopkins Sr

As a machinist, you could probably machine most of what i showed,

Yet, unless a metal component is required (for strength or wear), PLA works very often.

Learning is life.

Alan