Three Options For DIY Soft Jaws

In case of technical difficulty, this video is also posted on YouTube and FaceBook.

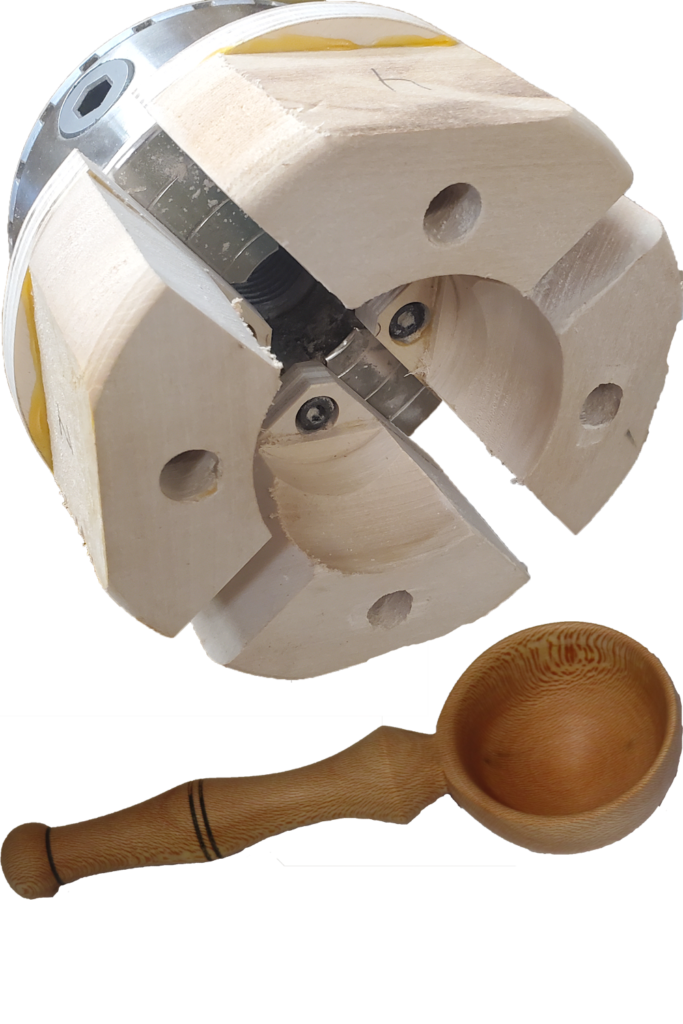

To turn my most recent scoop, I needed a set of soft jaws to use in the final stage of turning when I need to hollow the bowl portion of the scoop. Using my standard steel jaws would have damaged the scoop.

I have abandoned 3D printing for this project. Aside from the low strength of plastic in a high stress situation, I would have needed screws to hold the wood to the plastic. That means I risk hitting a screw with my lathe tools.

So, I transformed my 3D design to be a template with all the specs written on the template. I recommend you make your own template to match your chuck.

- Determine what bolt your chuck uses. The original bolt on my VicMarc is an M6 flat head bolt. I find it more convenient to use socket head bolts. Then the bolt sits flat on the surface instead of requiring a taper. Make sure you have a bolt long enough to accommodate your plywood but not to protrude beyond the chuck part it attaches to. So you do not have to figure this all out again, note the bolt spec on your template.

- BTW, the bolts you need will probably not be at a big box store. Check for a local bolt supplier.

- Remove and trace a jaw onto your template. Cut out your template.

For those with a VicMarc VM-120 chuck and access to a 3D printer. I have put my files on Printables.com at this link:

https://www.printables.com/model/256860-woodturning-chuck-jaw-templates-for-diy-soft-jaws

Enjoy.

Alan I am going to try to use your idea for a set of my Larger Nova chuck.

just use one of your Nova jaws as a pattern.

Alan