Woodturning – My DIY Steady Rest Is Still Steady

httpvhhttps://youtu.be/BBjhttps://youtu.be/BBjps1xNV3sps1xNV3s

For the convenience of some, this video is also posted on YouTube and FaceBook.

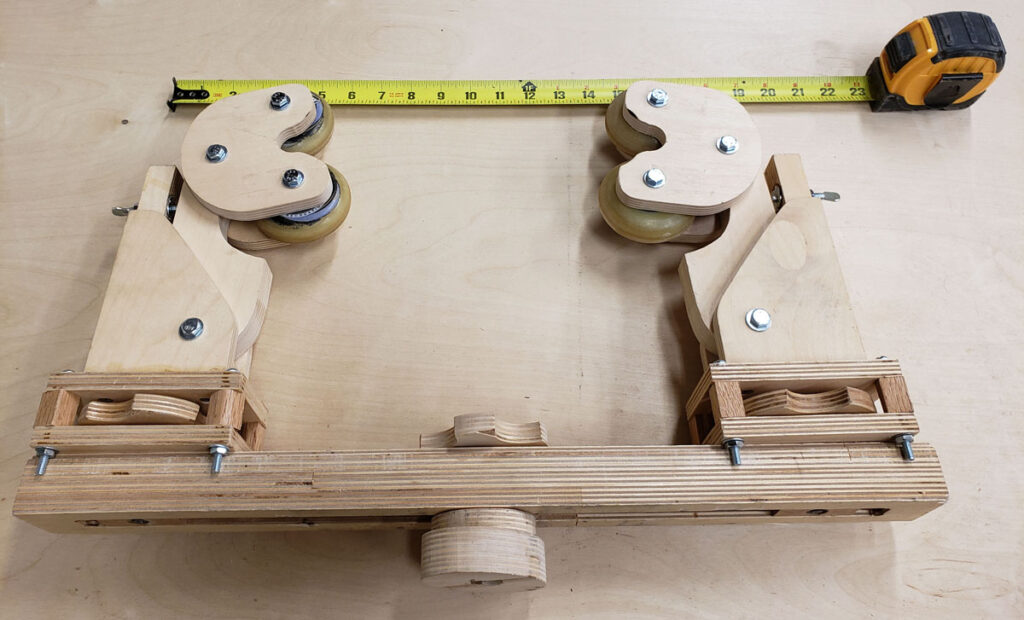

Several years ago, I researched steady rests for my lathe. A steady rest resists lateral pressure that may push the wood out of alignment or even out of the chuck. It works great on long spindles.

After making my steady rest, I revised it so that I could bring the tool rest closer to the steady rest. The original steady rest and the wide banjo on my lathe forced each other to be further away.

A revised base solved that problem. A tricky knob box reduced the need for a wider base. The knob box enabled my steady to be adjustable at right angles to the turning axis.

My revised steady has stood the test of time. I have not felt the need to change it again. There are minor improvements that could be made to make it prettier but would not change how it functions.

I have been asked about measured drawings. However, the steady rest should be customized for different lathes since axis height, bed gaps, bed thickness, bed width and turning styles all vary.

In this video, I am showing the principles involved with my steady rest. Once you understand the principles, you can adapt it to your lathe and style. I would appreciate hearing back what you have done to improve this design.

Previous Posts:

Update To My DIY Lathe Steady Rest

My DIY Lathe Steady Rest

Enjoy!

Great video. I’ve watched both of your prior videos before and still like your steady rest.

Thanks for your ideas.

Thank you Bob

Alan